What Do You Do if Your Bonded Ceramic Crown Falls Off?

“Can you re-glue my crown on doc?” your patient asks as he hands you a small wad of tissue paper. Many times, we unwrap that tissue paper only to discover a crown filled with the build-up and fragments of a tooth fractured to the gingival margin. Occasionally, however, an intact ceramic crown will be present with only some residual resin cement stuck to its intaglio surface. In these cases, the clinician may rebond the de-bonded crown by following a protocol to remove the residual cement without damaging the underlying ceramic.

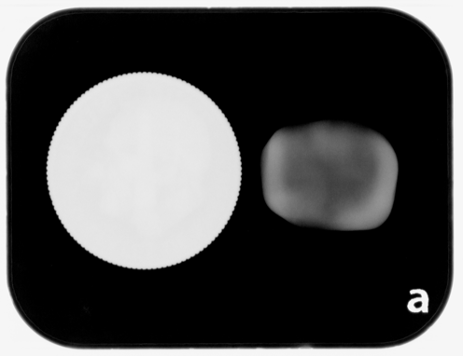

The first step is to determine the type of ceramic from which the crown is fabricated. A radiograph can be taken of the crown to determine its composition based on radiopacity. A crown that is as radiopaque as a coin is likely zirconia, whereas, a crown which is more radiolucent than a coin is likely a glass-based ceramic, such as porcelain or lithium disilicate.

Figure 1. A quarter (left) and lithium disilicate onlay (right)

Cleaning residual resin cement from zirconia can be achieved by sandblasting with 50 micron alumina at 2 bar (30 psi) pressure. Sandblasting zirconia with alumina particles does not reduce its strength due to its ability to heal cracks through transformation toughening. In fact, sandblasting zirconia with alumina particles is the laboratory procedure which is used to give zirconia surface texture for bonding.

Cleaning residual cement from the intaglio surface of glass-based ceramics, however, must be performed with more care in order to prevent damage to the underlying ceramic. If a glass-based ceramic, such as lithium disilicate, is sandblasted with 50 micron alumina at 2 bar pressure, it will lose 25% of its strength. Grinding the residual cement from lithium disilicate with a coarse diamond bur will reduce its strength and may affect the internal fit of the restoration.

One option to remove cement from lithium disilicate is to place it in a ceramic furnace in the following program: stand-by temperature (B) = 403°C, closing time (S) = 03:00, temperature increase (t) = 15°C, holding temperature (T) = 550°C, holding timer (H) = 05:00, vacuum on temperature (V1) = 403°C, vacuum off temperature (V2) = 550°C, and cool down gradient (L) = 0. By keeping the holding temperature below 590°C (the nucleation temperature for lithium metasilicate crystals), the strength and translucency of the crown should not be affected. After the crown is removed from the furnace, small pieces of burned cement will be present that can be cleaned in an ultrasonic bath or with an alcohol wipe.

Another option to clean residual cement from lithium disilicate is to sandblast it with 50 micron glass beads. Glass beads are an alternate sandblasting particle that are less abrasive than alumina particles. Glass beads can be thought of as small tennis balls as they are round and soft, whereas alumina particles are like small rocks as they are hard and irregular in shape. Glass beads used at 2-4 bar (30-60 psi) pressure are able to remove excess resin cement without affecting the strength of the underlying ceramic.

Figure 2. Sandblasting residual cement from a lithium disilicate onlay with 50 micron glass beads

Once the residual cement is removed from the internal surface of the glass-based ceramic materials, the surface needs to be re-etched because the etch pattern is dulled with cement removal. Lithium disilicate materials are etched between 20-30 seconds (depending on manufacturers recommendations) with 5% hydrofluoric acid and feldspathic porcelain is typically etched between 60-120 seconds with 5-10% hydrofluoric acid seconds (depending on manufacturers recommendations). After etching residual salts may be removed by cleaning with 37% phosphoric acid.

Observation of debonded crowns may help us improve our bonding protocol. If the resin cement is stuck to the intaglio of our crowns (as described in this article), the bond failed at the interface with the tooth. Perhaps improvement is need in isolation, clean-up of the tooth, or the bonding protocol to the tooth. If the resin cement is stuck predominantly to the tooth, perhaps the bonding protocol to the ceramic needs to be improved.

About the author:

Nathaniel Lawson, DMD, PhD

Dr. Lawson, is the Director of the Division of Biomaterials at the University of Alabama at Birmingham School of Dentistry and the program director of the Biomaterials residency program. He graduated from UAB School of Dentistry in 2011 and obtained his PhD in Biomedical Engineering in 2012. He has served as an investigator on over 50 clinical and laboratory research grants, and published over 150 peer reviewed articles, book chapters, and research abstracts. His research interests are the mechanical, optical, and biologic properties of dental materials and clinical evaluation of new dental materials. He was the 2016 recipient of the Stanford New Investigator Award and the 2017 3M Innovative Research Fellowship both from the American Dental Association. He serves on the American Dental Association Council of Scientific Affairs and is on the editorial board of The Journal of Adhesive Dentistry and Compendium. He has lectured nationally and internationally on the subject of dental materials. He also works as a general dentist in the UAB Faculty Practice.